Siemens to Construct Long Product Rolling Mill in the UAE

08/16/2013 - Siemens Metals Technologies has received an order from United Steel Industries LLC to construct a 950,000 tons per year long product rolling mill in the United Arab Emirates.

The plant will be built in the Fujairah Free Zone, and designed for a production capacity of up to 950,000 tons of structural steel per annum. It will comprise a bar mill for rebars and a wire-rod line, which will be able to produce both rods and wire coils. The value of the order lies in the double-digit million euro range. The new rolling mill is scheduled to come into operation in mid-2014.

Siemens had originally received the order to supply the equipment for the long product rolling mill in 2006. The original order also included the services of site project management for the equipment included in customer's scope. The project was suspended in 2008 on account of the financial crisis, and those parts of the plant which had already been delivered were put into storage. Work was resumed on the construction site in Fujairah in May 2012. The current order for Siemens comprises the erection of the supplied technological equipment as well as additional services for the site project management.

The merchant bar line will consist of 21 rolling stands, a heat-treatment system, a 120-meter cooling bed, as well as machines for counting, bundling and binding the bars. The maximum rolling speed will be 16 meters per second. The diameters of the rods will range from 10 mm to 40 mm. The wire rod mill will reach speeds of up to 105 meters per second. It will be able to produce either rods or wire coils, with diameters ranging from 5.5 mm to 16 mm. The equipment to be supplied by Siemens includes a ten-stand monoblock finishing mill, pinch rolls, the laying head, a cooling conveyor, and machines for forming and compacting coils. The scope will also include shears to crop and cut the end products to size on both rolling lines. Siemens will also supply a dedicated water treatment plant of approximately 2,000 m3/h capacity, and a compressed air station of approximately 2,500 Nm3/h capacity. All the electrical part will also be supplied by Siemens, including the power equipment with over 40 MW of motors and drives, and automation equipment with PLCs, HMIs, and Siroll packages.

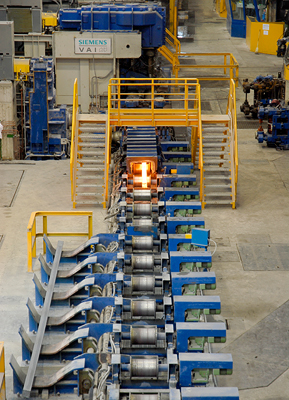

Pictured below: Roller table to a continuous rolling mill supplied by Siemens

.jpg?lang=en-US&ext=.jpg)